Services

It’s not what we do, it’s how we do it.

Draper Elevator Interiors is a one stop shop for total elevator cab solutions. Our services cover every phase of a project’s life cycle – including design, fabrication and installation. With over 25 years of experience we have created and refined a process that offers creative and unique resources to simplify your experience. We take great pride in fabricating quality products that are completed ON TIME! We aim to lead the industry in reliability and trust. At Draper, we work hard to ensure the end product meets or exceeds your expectations – we offer the following services listed below to help you visualize and stay informed on all details and aspects specific to you project.

Design Consultations & Project Specification

One of our absolute favorite things to do is to host clients for design consultations either in house or virtually. Design consultations are a great way to get project planning started off on the right foot. Here, clients can share their expectations and goals as they relate specifically to their project. Key discussion points here include – budgets, schedule, design concepts, material/durability and specification creation. Our showroom has a vast material library. Here clients can see first-hand what a material looks like exactly and even test the level of their durability. Please contact us to schedule a design session today!

3D Cab Renderings

See your design concepts brought to life in 3-D! Draper offers photo realistic three-dimensional elevator cab renderings for your visual aide. This popular service allows clients to see how their material selections are put together prior to proceeding with manufacturing. Often renderings are used for promotional purposes such as a presentation board for building tenants to see what the future renovation will look like or as a design board for architects and designers.

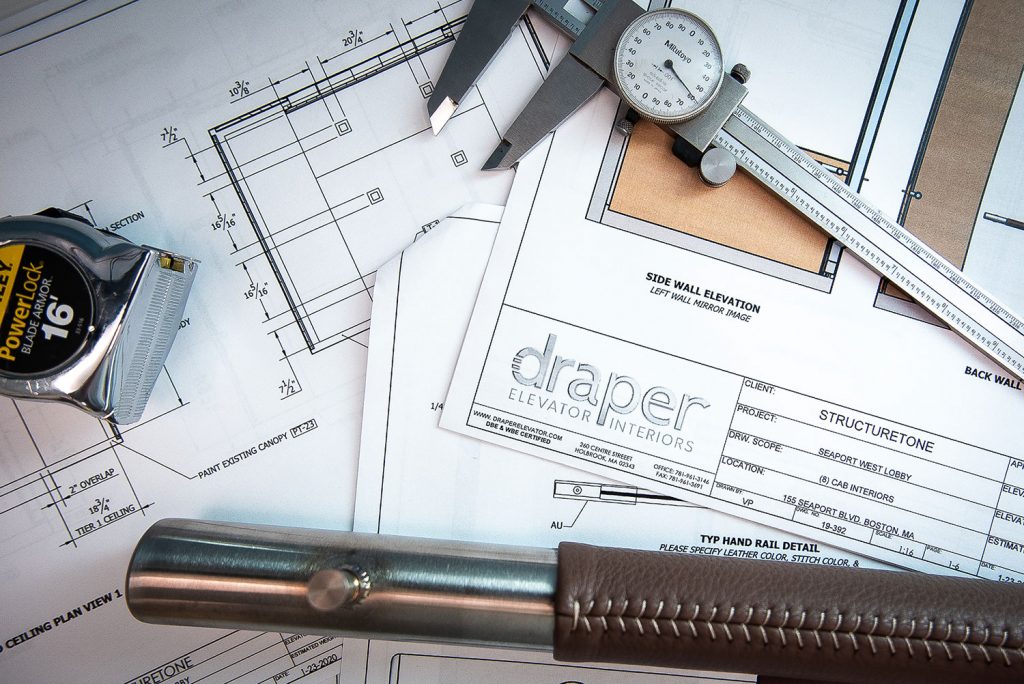

Engineering & CAD Drawings

Draper uses state of the art computer aided design software to formulate shop drawings of all our products. Our cab submittal drawings are laid out to scale and include views of all details and conditions. Additional project specific information includes weight calculations and a bill of materials. When appropriate 3D models will be included to complement the 2D drawings which display both plan and elevation views.

State Of The Art Project Management

At Draper we take great pride in our project management. It is here where we believe customers will notice the greatest difference when deciding on a cab vendor. It’s not only what we do, it’s how we do it. The success of any project is determined long before material arrives to a job site. We offer a project management service that allows customers to track their projects status at all times. Client status boards (as seen above) can be sent out upon request or monthly for high volume customers. If installed your project is installed by a Draper Elevator Interiors, you will be sent a completion report displaying the scope of work completed, photos of the cab prior to being turned over to the public. Avoid costly punch list aggravation! Completion reports are time stamped documentation.

Custom Fabrication

Draper Elevator Interiors is a custom manufacturer of elevator cabs and elevator cab interiors. Our shop is equipped with state of the art precision equipment and tooling. There is almost no limit as to what can be accomplished when designing a custom fabricated interior. Our facilities include full metal, wood working and finishing capabilities. For reference and inspiration of what those resources can produce please visit our portfolio page. If you can visualize it, we can build it. All shapes and sizes, materials and finishes we work with it all.

Mock-Up Reviews

As helpful as drawings, renderings and material samples are there is no substitute for seeing the real thing in full scale. To get the true sense of how materials will interact with each other, how lighting will affect the finishes sometimes can only be determined by reviewing it once assembled. On large scale projects it can be prudent to set up a mock-up review meeting at Draper’s facility to walk through and closely look at all the details prior to continuing our manufacturing of multiple elevators. And even sometimes if it is a single elevator but there is a highly custom element to it and can prove worthy of an in house review. This is an added measure and a final check point to ensure customer satisfaction.